[ivory-search id="9035" title="Default Search Form"]

- HOME

- SPRAY NOZZLE

- OUR SOLUTIONS

- MISTING SYSTEM

- DUST SUPPRESSION SYSTEM

- FOG / MIST CANNONS

- DRY FOG DUST SUPPRESSION SYSTEM

- DUST SUPPRESSION SYSTEM FOR MINES

- DUST SUPPRESSION SYSTEM FOR CRUSHER PLANTS

- DUST SUPPRESSION SYSTEM FOR COAL HANDLING PLANTS

- MINES HAUL DUST SUPPRESSION SYSTEM

- WATER SPRINKLER SYSTEM FOR COAL YARD

- PLAIN WATER DUST SUPPRESSION SYSTEM

- WET FOG DUST SUPPRESSION SYSTEM

- WAGON TIPPLER DUST DUST SUPPRESSION SYSTEM

- DUST SUPPRESSION SYSTEM FOR HOPPERS

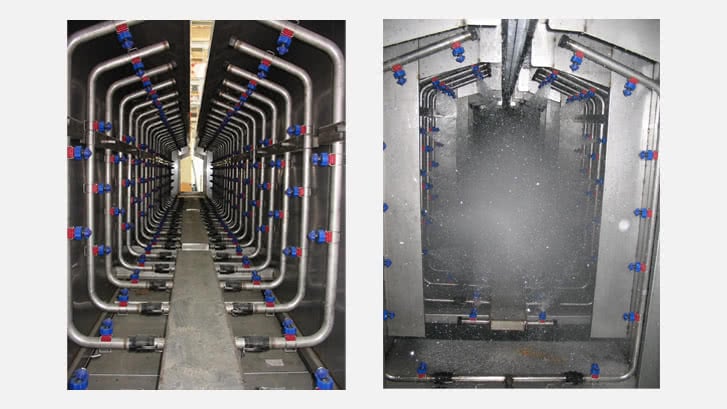

- WASTE WATER MIST EVAPORATER

- INDUSTRIES

- APPLICATIONS

- DUST SUPPRESSION SYSTEM

- FIRE PROTECTION

- FLUID MIXING AND AGITATION

- FOAM CONTROL

- FOOD PROCESSING

- GAS COOLING NOZZLES

- GAS SCRUBBING

- HUMIDIFICATION NOZZLE

- INJECTION

- LUBRICATION

- MOISTENING

- ODOUR CONTROL

- PRETREATMENT

- SPRAY COATING

- SPRAY COOLING SYSTEMS

- SPRAY DRYING

- SPRAY NOZZLES FOR CLEANING

- STORM TANK CLEANING

- TANK CLEANING NOZZLE

- GALLERY

- CONTACT US